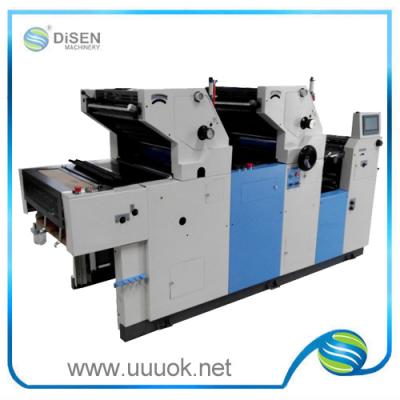

Features:

Using 120 ° heavy machine three drum angle,

wall thickening, the printing color than the horizontal machine is more full,

uniform, easy to install version, unloading version, the operation more

convenient and fast.

Each with three ink two water, a more

comprehensive system for the ink, the maximum guarantee of the full version of

the printing ink supply and inking effect, to ensure the completion of

high-precision printing quality. And a two-color printing can be completed, the

transfer of a unique paper transfer, the error is small, to ensure the

quasi-precision of two overlay. So that color printing, network cable pressure,

clear pattern, bright color does not string color. Greatly improve the

efficiency and reduce production costs, and fully embodies the characteristics

of the short version of fast printing.

Technical Parameters:

|

Model

|

DSS-247IIB

|

DSS-256IIB

|

|

Maximum paper size

|

470×365mm

|

560×390mm

|

|

Maximum printing area

|

450×345mm

|

550×375mm

|

|

Plate size

|

470×395×0.15 mm

|

560×417×0.15mm

|

|

Blanket size

|

470×420×1.95 mm

|

560×460×1.95 mm

|

|

Paper type

|

28-250g/ m2

|

|

Number of ink rollers

|

First printing unit:14 pieces(3 form ink

rollers)

Second printing unit 14 pieces(3 form ink

rollers)

|

|

Number of dampening rollers

|

5 pieces in each printing unit(2 form

rollers in each unit)

|

|

Registering mechanism

|

Roller type side lay

|

|

Printing speed

|

2000-8000 sheets/hour

|

|

Motor power

|

Main

motor1.5KW/220V

Air pump motor1.0KW/220V

|

|

Machine size

|

2300×935×1400mm

|

2300×1035×1400mm

|

|

Weight

|

1500KG

|

1560KG

|

Features:

1) 120 ° heavy machine with three drum

angles and thick wallboard.

2) compact structure, small footprint.

3) Each ink set adopts three ink two water

structure, with water evenly ink, printed goods shop full clear

4) The water, ink, pressure are used

pneumatic control, easy to operate, stable performance.

5) The transfer paper part of the unit

adopts the whole roller transfer paper structure, the paper is smooth and the

printing is accurate.

6) with non-stop cable-stayed version,

version of roller shaft fine-tuning device, version of the fast, convenient,

high efficiency.

7) The electrical part adopts the advanced

PLC control system, the degree of automation is high.

8) Toppan Printing (resin version), coding,

pressing the rice noodle can be completed (optional).

Pneumatic control features:

1. The pressure between the printing plate

cylinder, the impression cylinder and the blanket cylinder adopts the

pneumatically combined pressure, which is easier to be damaged under the tie

bar mode than the traditional electromagnet pull rod type structure. And the

pressure stability, network clear, good reduction.

2. Dial code with pneumatic mode, compared

with the traditional solenoid-type rod, especially in the printing with no

carbon copy paper jump code, the reaction is fast, easy to error.

3. Pneumatic control of vertical rice

noodle, horizontal rice noodle knife, instead of the traditional rice noodles

can not be free to jump characteristics, according to the need to set the

number of jumps. Pneumatic control can make the pressing pressure more stable.

4. Automatic lubrication oil supply system.

Can be based on the machine running automatically to the machine lubrication.

性能特点:

采用120°重型机三滚筒角度,墙板加厚,使印刷色彩比卧式机更饱满、均匀,便于装版、卸版,操作更方便、快捷。

每组采用三墨二水,更为完善的供墨系统,最大限度地保证了满版印刷的墨量供应和着墨效果,保证完成高精度的印刷品质。并且一次可以完成双色印刷,独特的纸张交接传递,误差小,保证两次套印的准精度。使彩色印刷、网线叠压,图案清晰,色泽亮丽不串色。极大的提高了效率,降低了生产成本,充分体现了短版快印的特点。

技术参数:

|

|

47IIB

|

47IIBNP

|

56IIB

|

56IIBNP

|

|

最大用纸尺寸Maximum

paper size

|

470×365mm

|

560×390mm

|

|

最大印刷面积Maximum

printing area

|

450×345mm

|

550×375mm

|

|

印版尺寸Plate

size

|

470×395×0.15 mm

|

560×417×0.15mm

|

|

橡皮布尺寸Blanket

size

|

470×420×1.95 mm

|

560×460×1.95 mm

|

|

纸张类型Paper

type

|

28-250g/ m2

|

|

墨辊数量Number

of ink rollers

|

First printing unit:14 pieces(3 form ink

rollers)

Second printing unit 14 pieces(3 form ink

rollers)

|

|

水辊数量Number

of dampening rollers

|

5 pieces in each printing unit(2 form

rollers in each unit)

|

|

套准机构Registering

mechanism

|

滚轮式侧拉规

Roller type side lay

|

|

印刷速度 Printing

speed

|

2000-8000张 /小时

2000-8000 sheets/hour

|

|

电机功率 Motor

power

|

主电机1.5KW/220V Main

motor1.5KW/220V

气泵电机1.0KW/220V

Air pump motor1.0KW/220V

|

|

机械尺寸Machine

size

|

2300×935×1400mm

|

2910×935×1400mm

|

2300×1035×1400mm

|

2910×1035×1400mm

|

|

重量

Weight

|

1500KG

|

1700KG

|

1560KG

|

1760KG

|

性能特点:

1)采用120°重型机三滚筒角度和加厚墙板。

2)结构紧凑,占地面积小。

3)每机组水墨部分采用三墨两水结构,着水着墨均匀,印品网店饱满清晰

4)着水、着墨、版压均采用气动控制,操作简便,性能稳定。

5)机组传纸部分采用全滚筒传纸结构,走纸平稳,套印准确。

6)设有不停机斜拉版、版滚筒轴微调装置,调版快捷、方便、工作效率高。

7)电器部分采用先进的PLC控制系统,自动化程度高。

8)凸版印刷(树脂版)、打码、压米线可一次完成(可选)。

气动控制功能特点:

1.印版滚筒、压印滚筒与橡皮滚筒之间的压力采用气动合压,较传统电磁铁拉杆式结构,解决了拉杆模式下易损坏的情况。且压力稳定,网点清晰,还原性好。

2.拨码采用气动模式,与传统电磁铁拉杆式相比较,特别是在印刷配联无碳复写纸跳码时,反应快,不易出错。

3.气动控制竖米线、横米线刀,代替了传统米线不可随意跳压的特点,可根据需要任意设置跳压张数。气动控制可使压线压力更稳定,。

4.自动润滑供油系统。可以根据机器运转情况自动给机器润滑。

Mobile website

Mobile website