- Embroidery Machine

- Cap/T-shirt Embroide Flat Embroidery Machine Manual Embroidery Machine Compounded Embroidery Machine Embroidery Machine Accessories

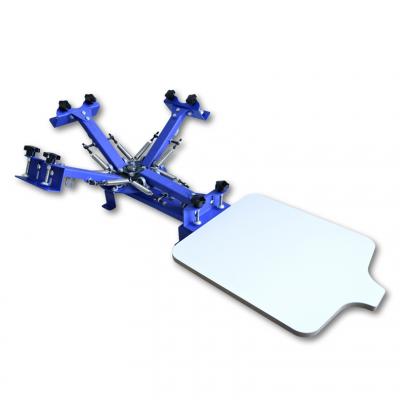

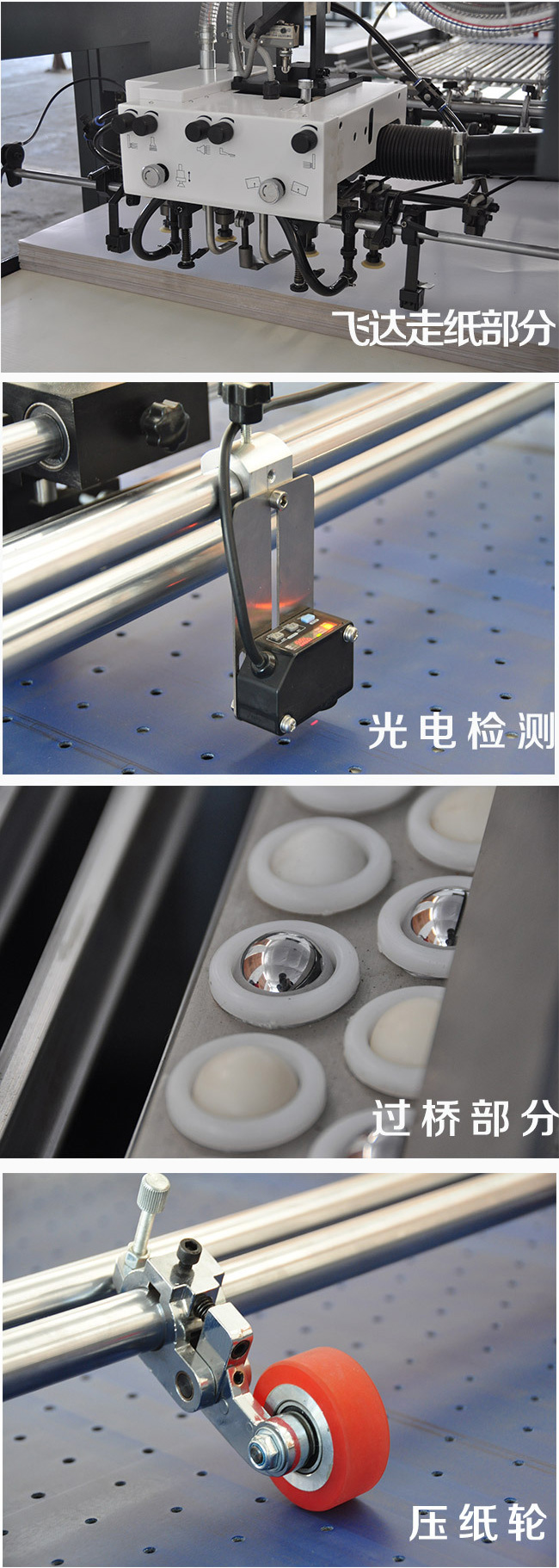

- Screen Printer

- Manual Screen Printing Machine Automatic Screen Printing Machine Printing Machine Matching Equipment Semi-automatic Screen Printer Curved Screen Printer

- Binding Machines

- Apron Binding Machines Wire Binging Machine Multifunction Binging Machine Single Coil Binging Machine

Mobile website

Mobile website